Automated, Continuous Chlorine Production for Medium to Large scale disinfection using seawater

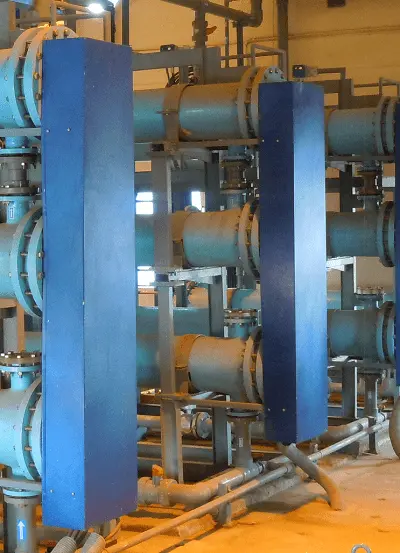

Pristine Water continuous production electrochlorinators are designed for the high-capacity production of sodium hypochlorite solution directly from seawater

Equipped with state-of-the-art PLC controls, our seawater Electrochlorination systems include all necessary instrumentation for automatic operation. Triggers, alarms, and sensors ensure safety and efficiency, making these systems suitable for cooling water treatment, seawater intake channels, and other disinfection needs.

Thermal and nuclear power plants near the seashore require massive amounts of water for cooling. Marine organisms like barnacles and oysters often proliferate in cooling water intake pipelines, causing operational issues. Chlorination is a widely accepted method to prevent fouling, and sodium hypochlorite produced from seawater is a safe, efficient alternative to chlorine gas.

Choose our seawater Electrochlorination systems for a robust, efficient, and safe solution to your high-capacity chlorination needs

Our systems are equipped with comprehensive instrumentation, including pressure gauges, flow meters, temperature controllers, level switches, and hydrogen detectors. These are connected to control panels, which may be relay-based or PLC-based, ensuring precise operation and monitoring. PLC systems interface with plant DCS through SCADA for enhanced control.

We use PVC or CPVC pipes, valves, and fittings in our sodium hypochlorite generation systems. These materials resist corrosion and are easy to fabricate and erect, ensuring long-lasting and reliable performance.